Anbao can customize and process non-standard flanges based on special parameters provided by customers. Although there are some standard specifications for flanges, there are also various differences in materials, sizes, connection methods, etc., to accommodate different usage environments and occasions.

View DetailsThe slip-on flange is one of the loose flanges that loosely fit over the protruding edge of containers or pipelines. The protruding edge of slip-on flanges can be produced via edge flanging, turning, or welding additional rings. It has the advantage that when the flange deforms, it does not generate additional torque on the container or pipeline. It is also easy to manufacture and can be made from different materials than the container or pipeline, which helps save precious metals. The disadvantage is that the flange thickness is relatively large. Thus, it is suitable for cases where the container or pipeline is lined with brittle materials and the pressure is not high.

View DetailsThe welding neck flange consists of the flange plate, the flange gasket and some flange bolts. The flange plate is the main part of the high-neck flange, primarily serving to connect pipes. The flange gasket is placed at the connection between the flange plate and the pipe, serving a sealing function. The flange bolts are used to secure the flange plate and the flange gasket. Welding neck flanges are typically made of materials such as carbon steel, stainless steel, and alloy steel. The carbon steel welding neck flanges are suitable for general industrial applications, stainless steel ones are suitable for precision instruments, food, pharmaceuticals, and other fields, while alloy steel ones are suitable for high-temperature and high-pressure working environments.

View DetailsThe socket welding flange achieves a tight connection in the pipeline system based on its internal convex and external concave geometric shapes. It is commonly used in the installation of various fluid pipeline systems in industrial engineering and construction fields. Its advantages include simple installation, easy disassembly, compact structure, good sealing performance, high load capacity, and strong reliability. Besides its important role in traditional industrial pipeline fields, in recent years, it has been widely applied in areas such as municipal construction, environmental protection, and agricultural irrigation. In municipal construction, it can be used in underfloor heating systems, central air conditioning, water supply and drainage pipelines, and fire systems. In the environmental protection field, it has broader application areas, such as wastewater treatment equipment, reverse osmosis systems, and chemical reagent transport pipelines.

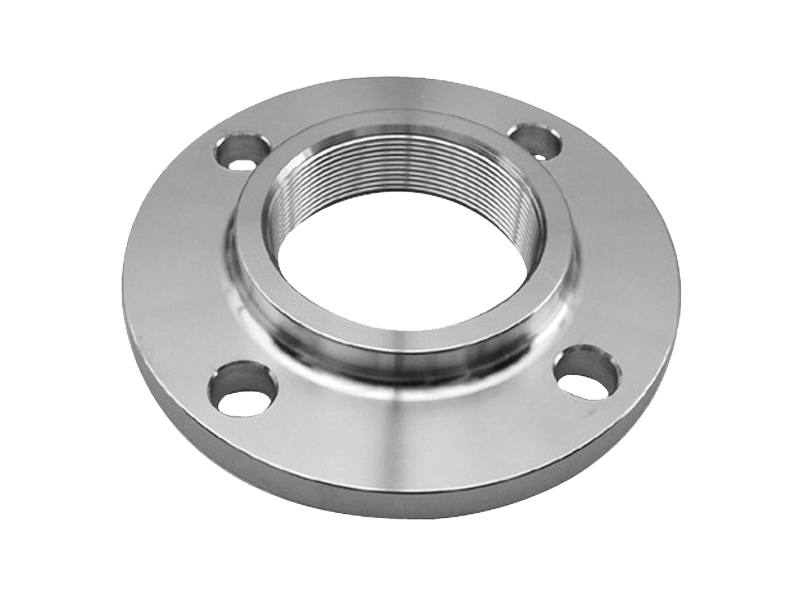

View DetailsThe threaded flange refers to a type of flange that connects to a pipe using threads. During design, it can be treated as a loose flange. The advantage is that it does not require welding, and the additional torque generated on the cylinder or pipeline when the flange deforms is very small. The disadvantage is that the flange thickness is large, resulting in higher costs. It is suitable for connecting high-pressure pipelines. A threaded flange has its inner hole machined into pipe threads and is matched with a threaded pipe for connection, making it a non-welded flange. Compared to flat welded flanges or butt-welded flanges, threaded flanges are convenient for installation and maintenance, and can be used in some pipelines where welding is not allowed. Additionally, alloy steel flanges have sufficient strength but are difficult to weld or have poor welding performance, so threaded flanges can also be chosen. However, under conditions of rapid temperature changes in the pipeline or temperatures above 260°C or below -45°C, it is recommended not to use threaded flanges to avoid leakage.

View DetailsThe lap joint flange has a fastening method of cross-lapping connection surfaces of two flanges. Therefore, it is also known as "overlapping flange" or "lapped flange". It consists of two parts: one part is the flange itself, and the other part is the overlapping component. The outer ring of the flange has threads to secure it to the overlapping component. The overlapping component consists of an inner ring with threads and an outer ring that extends outwards. The outer ring is connected to one flange, while the inner ring is connected to another flange. The lap joint flange is one of the commonly used connection methods in pipeline systems, with advantages such as simple installation, adaptability to various pipe specifications, and ease of adjusting structural length. When using The lap joint flange for butt welding, attention should be paid to the fixation of the overlapping component, appropriately controlling the applied force, and the cleanliness of the operating interface.

View DetailsAnbao can customize and process non-standard forgings according to the special parameters provided by customers. As for flanges, although there are some standard specifications, there are still various differences in materials, dimensions, connection methods, etc., in order to adapt to different usage environments and scenarios.

View DetailsThe blind flange is a flange without a hole in the middle, used to seal the end of a pipe. Its function is the same as that of a head and pipe cap, except that the blind flange seal is a removable sealing device, while the head seal is not intended to be reopened. There are various types of sealing surfaces, including flat, convex, concave-convex, tongue-and-groove, and ring connection surfaces. It is mainly used to completely isolate the production medium, preventing issues caused by improperly closed shut-off valves, which could affect production or even cause accidents. It should be installed at points requiring isolation, such as at the equipment connection, before and after shut-off valves, or between two flanges. The spectacle blind is commonly recommended.

View DetailsAnbao can customize and process non-standard forgings according to the special parameters provided by customers. As for flanges, although there are some standard specifications, there are still various differences in materials, dimensions, connection methods, etc., in order to adapt to different usage environments and scenarios.

View DetailsAnbao can customize and process non-standard forgings according to the special parameters provided by customers. As for flanges, although there are some standard specifications, there are still various differences in materials, dimensions, connection methods, etc., in order to adapt to different usage environments and scenarios.

View Details