ABOUT US

Anbao · Professional Flange Production Base

Shanxi Anbao, located in Dingxiang, the "Hometown of Forging in China", is a leading flange production and trading base in China. Founded in 2000, we have 25 years' experience in providing professional, high-quality flange solutions to customers worldwide. The integrated production factory covers an area of 80,000 m², and has a building area of 45,000 m². Our products are sold to the US, Brazil, South Korea and more. The projects we support cover the petroleum, chemical, machinery, power, construction, and coal-mining industries. Our flanges, made of carbon, alloy, and stainless steel, are available in both standard and customized types, featuring low-temperature resistance, corrosion resistance, and high strength. Nowadays, our annual output reaches to 20,000 tons, with 10,000 tons for export. We focus on innovation and quality, and have an independent inspection department. Holding ISO9001, PED, TUV, CRN certifications and multiple patents, we aim to offer better products and services, guided by our "quality delivers value" mission.

History

Registered Capital

Factory Area

Annual Production Output

Quality Delivers Value

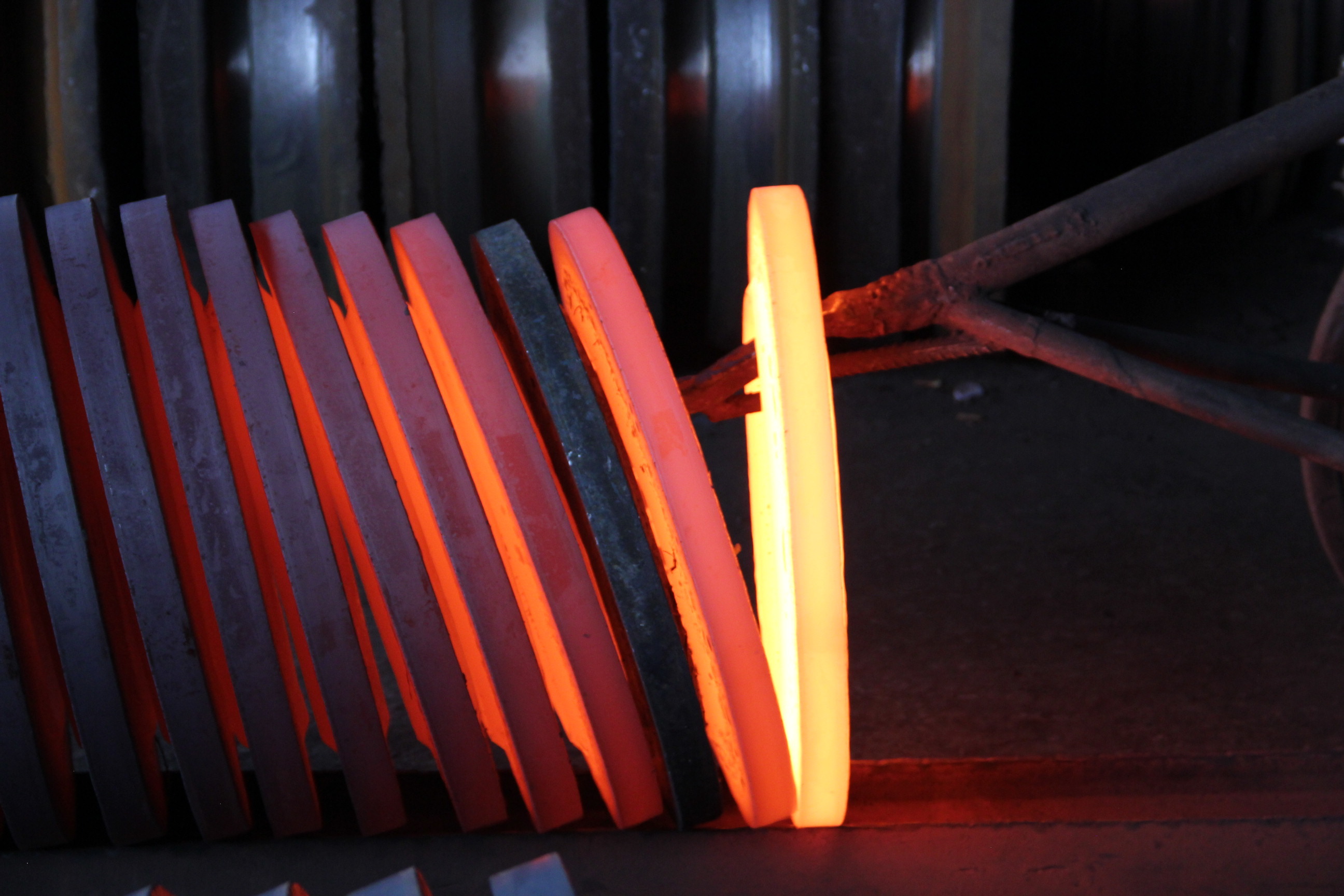

PRODUCTS

Product-Driven by Technological Innovation

EQUIPMENT

Equipment-Continuous Investment and Refinement

After several large-scale technological transformations, Anbao's technical equipment level now ranks at the forefront in the same industry. We own advanced forging and pressing processing equipment, including three-station die forging hydraulic presses, D81K-2000MM ring rolling machines, bidirectional trolley-type natural gas heat treatment furnaces, CNC lathes, and high-speed CNC drilling (milling) machines. In addition, for testing, Anbao is equipped with metallographic analyzers, spectrometers, ultrasonic flaw detectors, universal testing machines, and infrared thermometers. We can produce flanges and forgings of various materials, specifications, and standards according to customers' requirements.

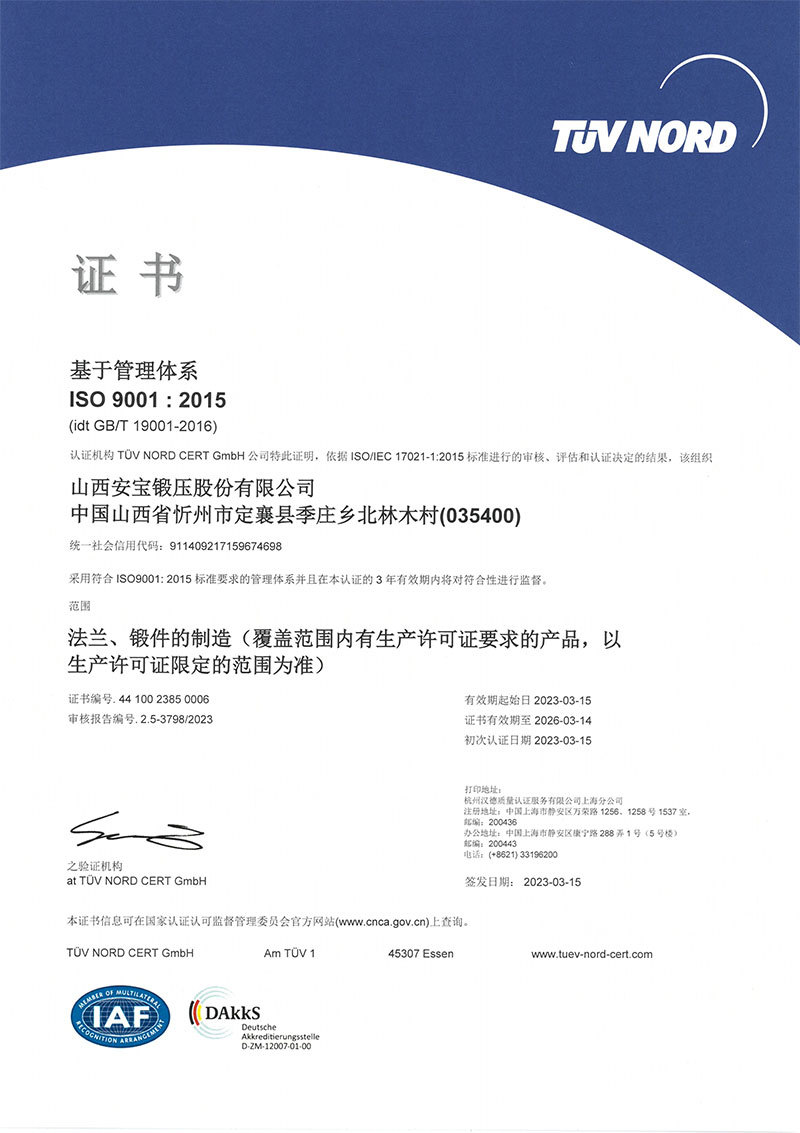

CERTIFICATE

Qualification · High Standard Quality Management

ISO 9001:2015

ISO 9001:2015

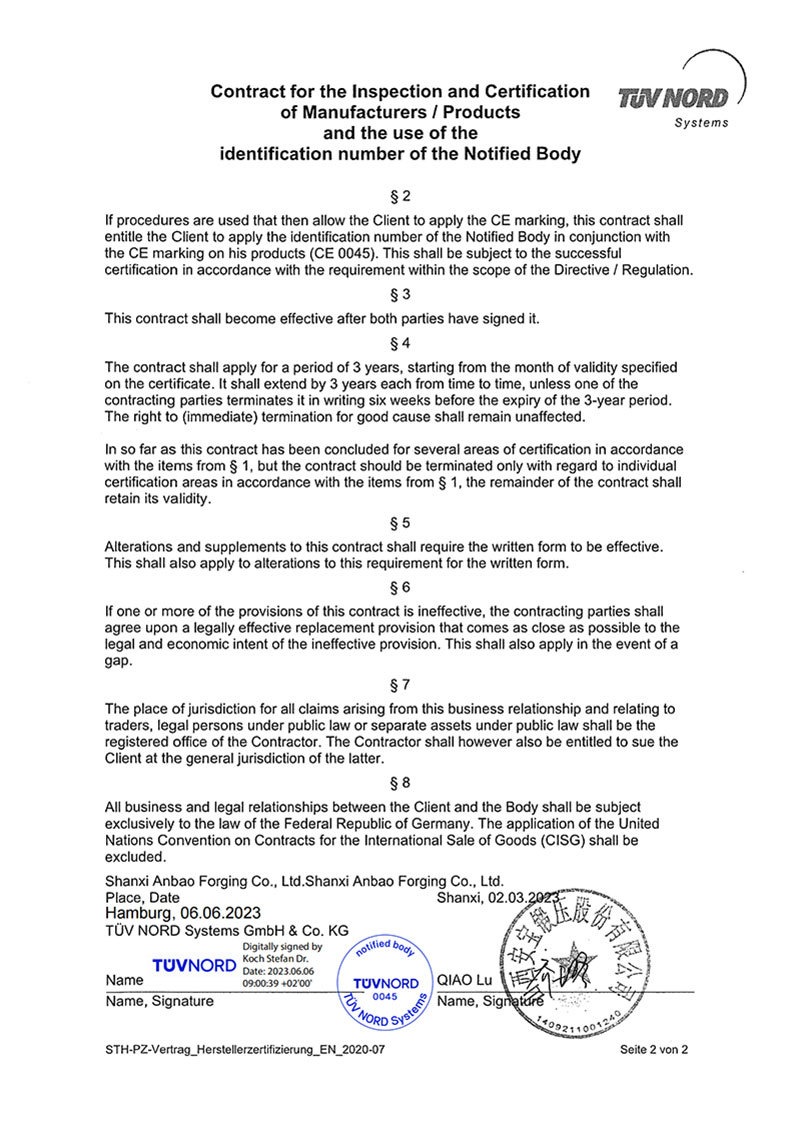

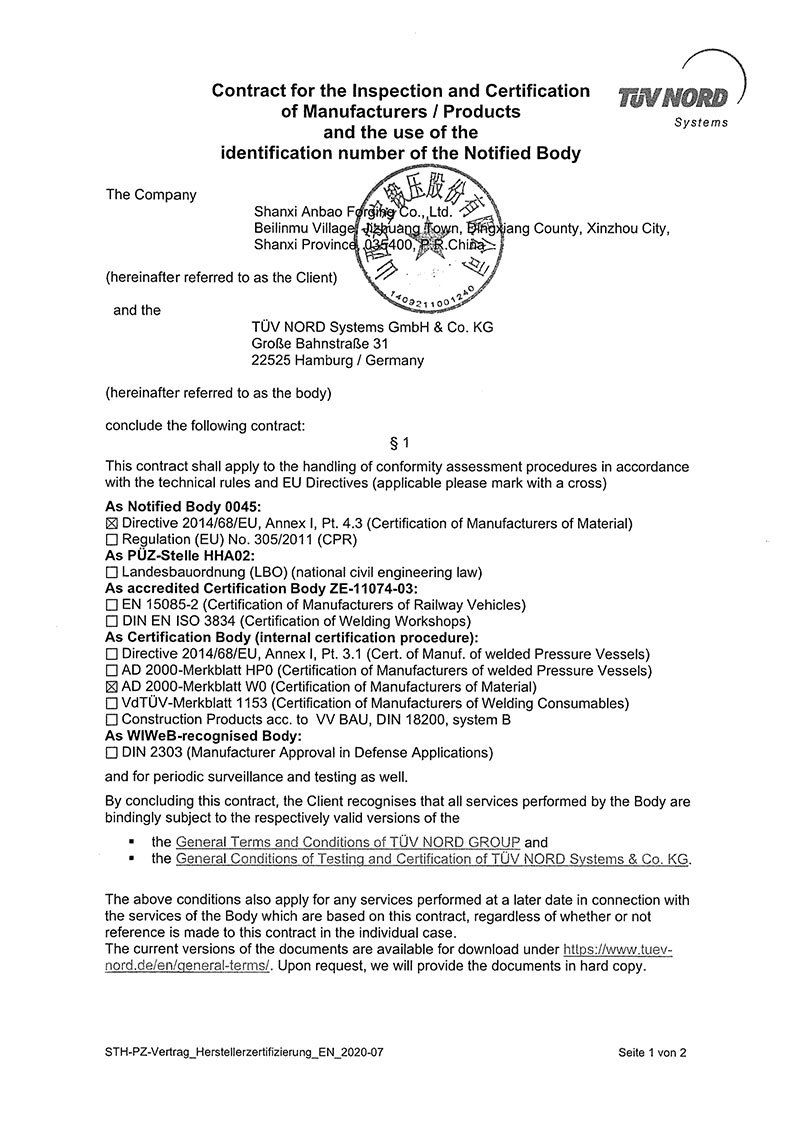

TUV Certificate

TUV Certificate

TUV Certificate

TUV Certificate